|

|

|

No. 6.3

Component Modifications and Additions OUTLINE This procedure covers the general guidelines for modifications that involve adding components.

TOOLS & MATERIALS Cleaner Cleaning Wipes Flux Microscope System Soldering Iron with Tips Solder GENERAL RULES

PROCEDURE

|

|

|||||||||||||||||||||||||||

|

Component Modifications and Additions Figures |

||

Figure 1: Radial lead component soldered to through hole component leads. Note: Leads of the radial component should not need to be inserted into the plated holes. |

Figure 2: Axial lead component soldered to through hole component leads. Note: Leads of axial component should not be inserted into the plated holes. |

|

Figure 3: Axial lead component soldered to adjacent axial lead component. Note: Added component may be stacked vertically or horizontally. |

Figure 4: Chip component soldered to surface mount component using jumper wires. Note: One lead of surface mount component is shown lifted. |

|

Figure 5: DIP component stacked and soldered onto another DIP component. One lead shown clipped. Note: Leads of added component should not be inserted into the plated holes. |

Figure 6: Chip cap bridging adjacent leads. |

|

Figure 7: Chip component bridging leads of surface mount component. |

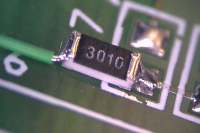

Figure 8: Chip component stacked onto another chip component. |

|

Figure 9: Surface mount component mounted upside down with jumper wires attached. Note: One lead is bent outward. |

Figure 10: DIP Component mounted upside down with jumper wires attached. |

|

Figure 11: Chip component mounted to one pad only. |

Figure 12: Radial lead component mounted upside down. Note: Insulate leads to avoid contact with component body. |

|

|

|

|

|

| |