No. 4.6.3

Edge Contact Repair/Rework, Plating Method

OUTLINE

This method is used to replate edge contacts by selective swab plating. Edge

contacts may require replating if they become contaminated with solder or are

scratched during handling. Other applications may arise when the plating on the

edge contacts does not meet the minimum thickness specification or if the

specification changes.

This electroplating process uses a DC power supply. One lead is connected to

the connector edge contacts that need plating. A second lead is connected to the

plating probe. The plating probe has an anode fastened to the tip. The anode has

absorbent wrapping. The anode is dipped into high-speed proprietary plating

solutions. When the saturated anode is swabbed across the circuit board connector

edge contacts, the metal contained in the solution is plated wherever electrical

contact is made. Prior to replating any solder contamination must be removed.

CAUTION

This method can be used to replate any metal surface including connector edge

contacts, but it is essential that the surface to be plated is free of deep

scratches, nicks, pin holes or other defects. If the edge contacts need to be

replaced see appropriate procedure.

SAFETY

A thorough review of this method should be made before repairs are attempted.

Technicians should become familiar with the tools included and should practice

on scrap circuit boards.

To expect the best results a clean work environment is essential. A smooth

work surface and good lighting are recommended. Safety glasses and safety gloves

should always be worn when handling hazardous chemicals.

The work area should be adequately ventilated. It is particularly important

to have adequate ventilation when using gold solution, since gold solution

contains a very small percentage of free cyanide. If ventilation is not

adequate, use a fan to move fumes away from the operator.

CAUTION

It is essential to follow the manufacturer's instruction supplied with the

plating equipment.

| ACCEPTABILITY REFERENCES |

| IPC-A-600 |

2.0 |

Externally Observable Characteristics |

| IPC-A-610 |

10.0 |

Laminate Conditions |

| |

| PROCEDURE REFERENCE |

| CTC-7721 |

1.0 |

Foreword |

| CTC-7721 |

2.1 |

Handling Electronic Assemblies |

| CTC-7721 |

2.2 |

Cleaning |

| IPC-7721 |

4.6.3 |

Edge Contact Repair/Rework, Plating Method |

TOOLS & MATERIALS

Abrasive Pad

Board Support

Cleaner

Conductive Pen

Desoldering Braid or Desoldering System

Eraser Stick

Flux, Liquid

Gloves, Antistatic

Gold Contact Plating System

Knife

Peel Testing Tape

Pin Fixtures

Plating Anodes

Plating Solution, Gold

Plating Probes

Plating Solution, Electroclean

Plating Cables

Plating Solution, Nickel

Plating Solution, Solder Strip

Plating Tape

Power Supply

Probe Clip

Rinse Tray

Rinse Bottle

Safety Glasses

Soldering Iron

Solder

Solution Swab

Solution Cups

Solution Tray

Tape, Kapton

Thickness Measuring System, Gold and Nickel

Water Sprayer

Wipes

Wire, Bus, 30 AWG

Work Sink

PREPARATION - Remove Solder Contamination

CAUTION

Safety glasses and safety gloves should always be worn when handling hazardous

chemicals. Do not work within a small enclosed room without supplemental

ventilation. If ventilation is not adequate, use a fan to move fumes away from

the operator.

- Clean the rework area.

- Apply plating tape to the circuit board surface surrounding the area to be

reworked. The plating tape will protect adjacent components and the circuit board

surface from unwanted exposure to stripping and plating solutions.

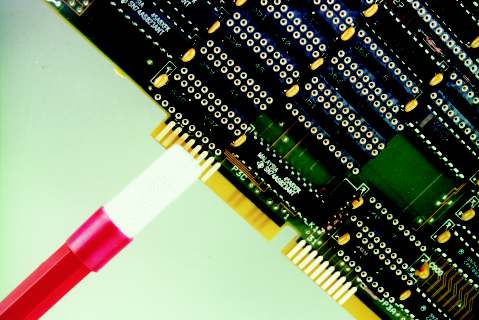

- Flow solder over the entire area of any contacts that have contamination

using a soldering iron. This provides a more even surface when plating. Remove

the bulk of the solder contamination using desoldering tools or desoldering

braid. (See Figure 2).

- Clean the area.

- Place the circuit board on the board support so that the leading edge overhangs

the rinse tray.

- Swab the solder stripping solution over the solder contamination using a

swab. Swab the surface until all remaining solder has been stripped off. (See

Figure 3).

- Thoroughly rinse the entire area with water. (See Figure 4).

- Mildly buff the contacts using abrasive pad. Mild buffing will prepare the

surface for plating and remove any remaining solder contamination.

- Thoroughly rinse with water to remove any residue.

PREPARATION - Remove Poor Plating or Surface Defects

- Clean the rework area.

- Apply plating tape to the circuit board surface surrounding the area to be

reworked. The plating tape will protect adjacent components and the circuit board

surface from unwanted exposure to stripping and plating solutions.

- Clean the area.

- Buff the contacts using an abrasive pad. Buff the contacts until all

defective or poor plating is removed.

- Burnish small scratches. Use the tip of the Tech-Pro Burnisher to work the

copper material into the scratch and smooth out the area. Finish by mildly

buffing the area to remove any minor burnishing marks. If there are large

scratches the contact may need replacement. See Procedure Number 4.6.1 or 4.6.2.

- Thoroughly rinse the entire area with water to remove any residue.

BUSING

A conductive bus must be made to all the contacts that need plating. There are 4

basic connection options.

NOTE

Making a reliable bus connection is the most important step in plating. All

sorts of problems will be eliminated by taking the time to make a reliable bus

connection.

BUSING - Wire Soldered to Edge (Option 1)

CAUTION

When finished, this method will leave a small unplated line along the inner tip

of each contact.

- Apply Kapton tape to all the contacts to be plated. The High

Temperature Tape should cover the entire contact except for a small line along

the inboard edge. The Kapton tape will prevent further solder

contamination.

- Solder a wire directly to the inboard tip or connecting circuit of each

contact to be plated. The smallest amount of solder should be used to prevent

further contamination. (See Figure 5).

BUSING - Conductive Paint Applied to Edge (Option 2)

CAUTION

When finished, this method will leave a small unplated line along the inner tip

of each contact.

- Apply Kapton tape to all the contacts to be plated. The High

Temperature Tape should cover the entire contact except for a small line along

the inboard edge. The Kapton tape will prevent the conductive paint

from contaminating the contact surface.

- Apply a thin coating of conductive paint directly to the inboard tip of each

contact to be plated. The conductive paint should extend out to one edge so that

a clip can be applied to make electrical connection. (See Figure 6).

BUSING - Mechanical Probe, Individual Contacts (Option 3)

- Each contact needing plating can be individually probed using the plating

probe. Touch the tip of the plating probe to the inboard edge of each contact or

to the connecting circuit as each solution is applied during the plating

process.

BUSING - Pin Fixture, Multiple Contacts (Option 4)

- Make a mechanical connection to each contact using a pin fixture. The pin

fixture has spring loaded contact pins on centers matching the spacing of the

edge contacts to be plated. The contact pins make direct mechanical connection

to the inboard tip of each contact, the connecting circuit trace or a connecting

plated through hole..

PROCEDURE - Plating Process

- Place the circuit board on the board support so that the leading edge overhangs

the rinse tray.

- Make the cathode connection (-) to the circuit board by using a plating probe or

probe clip. Connect the probe clip directly to the wire bus connection or to the

edge where conductive paint has been applied. The cable should be connected to

the (-) or black jack on the power supply.

- Connect the plating probe to the power supply (+) or red jack. (See Figure

7).

- Set the output current on the power supply to setting recommended by the

equipment manufacturer. Refer to Table 1 for general voltage/time settings.

- Dip the plating probe into the electroclean plating solution. Wait a few

seconds for the solution to saturate the absorbent wrapping.

- Swab the entire surface to be plated by brushing the surface with the

saturated plating probe. The plating probe should be moved back and forth

briskly to prevent burning and to provide even coverage. (See Figure 8) Swab the

area for the time recommended by the equipment manufacturer. Refer to Table 1

for general voltage/time settings.

- Thoroughly rinse the entire area with water. Any burning or darkening of the

contacts may be removed with an abrasive pad. Saturate the abrasive pad and the

PC board surface with water and lightly buff the contacts until all evidence of

the burning or discoloring is removed. Rinse the entire area with water.

CAUTION

Do not allow the rework area to dry out between steps. The water coating

prevents oxidation.

- Connect the nickel plating probe to the power supply (+) or red jack.

- Set the output current on the power supply to setting recommended by the

equipment manufacturer. Refer to Table 1 for general voltage/time settings.

- Dip the plating probe into the nickel plating solution. Wait a few seconds

for the solution to saturate the absorbent wrapping.

- Swab the entire surface to be plated by brushing the surface with the

saturated plating probe. The plating probe should be moved back and forth

briskly to prevent burning and to provide even coverage. Swab the area for the

time recommended by the equipment manufacturer. Before rinsing, lightly buff the

contacts with an abrasive pad. Refer to Table 1 for general voltage/time

settings.

- Thoroughly rinse the entire area with water.

- Connect the gold plating probe to the power supply (+) or red jack.

- Set the output current on the power supply to setting recommended by the

equipment manufacturer. Refer to Table 1 for general voltage/time settings.

- Dip the plating probe into the gold plating solution. Wait a few seconds for

the solution to saturate the absorbent wrapping.

- Swab the entire surface to be plated by brushing the surface with the

saturated plating probe. The plating probe should be moved back and forth

briskly to prevent burning and to provide even coverage. Swab the area for the

time recommended by the equipment manufacturer. Refer to Table 1 for general

voltage/time settings.

- Thoroughly rinse the entire area with water.

- Remove and discard all plating tape and thoroughly rinse the area with

water. Dry the area using a water/air sprayer or wipes.

- Remove the wire or conductive paint used to bus the contacts.

CAUTION

Apply Kapton tape to protect the contacts from further contamination

while removing the bus connection.

- Thoroughly rinse the entire area with deionized water or rinse the circuit board

in an aqueous water cleaning system.

Table 1

Typical Voltage/Time Settings

| Surface Area

| Electroclean

| Nickel

| Gold

|

| Volts |

Time |

Volts |

Time |

Volts |

Time |

| <.01 in2 |

10.0 VDC |

5 sec. |

4.0 VDC |

10 sec. |

3.0 VDC |

10 sec. |

| .01 - .05 in2 |

10.0 VDC |

5 sec. |

4.0 VDC |

30 sec. |

3.5 VDC |

20 sec. |

| .05 - .10 in2 |

10.0 VDC |

5 sec. |

4.0 VDC |

1.0 min. |

4.0 VDC |

30 sec. |

| .10 - .20 in2 |

10.0 VDC |

10 sec. |

4.0 VDC |

2.0 min. |

4.0 VDC |

1.0 min. |

| .20 - .30 in2 |

10.0 VDC |

10 sec. |

4.0 VDC |

2.5 min. |

4.0 VDC |

1.5 min. |

| .30 - .40 in2 |

10.0 VDC |

10 sec. |

4.0 VDC |

3.0 min. |

4.0 VDC |

2.0 min. |

| .40 - .50 in2 |

10.0 VDC |

20 sec. |

4.0 VDC |

4.0 min. |

4.0 VDC |

2.5 min. |

| .50 - .60 in2 |

10.0 VDC |

20 sec. |

5.0 VDC |

5.0 min. |

4.0 VDC |

3.0 min. |

| .60 - .70 in2 |

10.0 VDC |

20 sec. |

6.0 VDC |

6.0 min. |

4.0 VDC |

3.5 min. |

| .70 - .80 in2 |

10.0 VDC |

30 sec. |

6.0 VDC |

7.0 min. |

4.0 VDC |

4.0 min. |

| .80 - .90 in2 |

10.0 VDC |

30 sec. |

6.0 VDC |

7.5 min. |

4.0 VDC |

4.5 min. |

| .90 - 1.00 in2 |

10.0 VDC |

30 sec. |

6.0 VDC |

8.0 min. |

4.0 VDC |

5.0 min. |

Notes:

- Surface Area is the total area being plated during each swab plating

operation.

- Voltage and Time setting shown in Table 1 are for a minimum of .000100"

Nickel and .000050" Gold.

- Settings are a guide. For precise thickness requirements the final thickness

should be verified with proper measuring equipment.

EVALUATION

- The rework area should be checked by measuring the thickness of the nickel

and gold to make sure they meet the minimum thickness requirement.

- The plating bond may also be checked by doing a peel test using peel testing

tape.

- Visually examine the rework area for color and luster.

|