|

|

|

Base Board Repair

What happens to an assembled circuit board with a broken corner? Can it be repaired reliably? It certainly can if you have technicians who are trained and experienced at this sophisticated type of repair. At Circuit Technology Center, we can reliably repair nearly any type of base board defect including impact damage, burns, delamination, blistering, measling, warp, routing errors and more. We can also repair defects in coatings, solder mask and legend. For most minor repairs, we use high strength, thermoset epoxy, blended with color agents to match surface colors and textures. We replace severely damaged base board material by bonding in replacement material using a tongue-and-groove joint. These types of circuit board repairs may seem exotic, but the procedures are documented and recommended by the IPC. Additionally, these procedures have been perfected by the team of highly qualified technicians at Circuit Technology Center. Base Board Rework Removing excess base board material due to errors or modifications is normally completed using milling machines The circuit board assembly is carefully and precisely clamped in place and carbide cutters are used to machine away the excess material to meet new dimensions, or to add holes, slots or grooves. More challenging than removing base board material is the process of adding base board material to conform to the original or modified dimensional criteria. This is done by machining a groove in the circuit board edge and then material is added using a tongue and groove joint technique. Final trimming may be completed using the precision and accuracy of milling machines This tongue and groove joining method was pioneered by Circuit Technology Center and is now an IPC recommended method for base board rework. Non plated mounting and tooling holes are reworked using another technique. Here we use a dowel shaped replacement section of matching base board material that is bonded in place, machined flush, and finally drilled as needed. Slot modification is a type of base board repair used to modify or repair a key slot, or other cutout in a printed board or assembly. A replacement piece of matching board material is epoxied into the area needing repair. A new cut is then machined into the repaired area if needed. Real Problems - Real Solutions Improperly setup routing equipment trimmed 420 circuit boards to the wrong size. Instead of routing the circuit boards 6.60" wide, they were routed 6.06" wide. If the PC boards were routed oversize, instead of under size, the correction would be as simple as milling off the excess material. Unfortunately the error was not discovered until the boards were assembled. Believe it or not, things like this actually happen. The call went out to Circuit Technology Center. A modified version of the edge transplant method was used. As described in the procedure was machined along the entire edge that needed material to be added. Oversize replacement pieces were fabricated to fit along the entire length of the edge. Once the new material was bonded in place the excess material was removed by milling. The boards were valued at $700 each. Rework charge was $37 per board. Total Value $294,000 - Total Charge $15,540 - Total Savings $278,460 Refer to the Reference Procedures below for a detailed review of the step-by-step procedures we follow to repair and rework circuit boards. Reference Procedures - Service Charges

Pricing will vary depending on extent of delamination area; proximity to adjacent circuitry; or if milling vs. injection is used. Note 2: Requires high temperature. Review material specifications before proceeding. |

|

|

|

|

|

| |

Broken corners, a common occurrence.

Broken corners, a common occurrence.

Damaged

Damaged  Milling machines are often used for accuracy when reworking circuit boards.

Milling machines are often used for accuracy when reworking circuit boards.

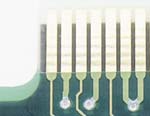

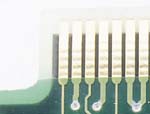

This board needed material added along the edge adjacent to the edge contact.

This board needed material added along the edge adjacent to the edge contact.

Material was added along the edge using the IPC recommended

Material was added along the edge using the IPC recommended