No. 8.5.3

Component Replacement, Surface Mount BGA Components, Hot

Gas/Air Method

OUTLINE

This procedure covers the most commonly used methods for replacing Plastic

Ball Grid Array (PBGA) components and Ceramic Ball Grid Array (CBGA) components. These packages are typically referred to as Plastic Ball Grid Array

(PBGA) or Tape Ball Grid Array (TBGA) or Chip Scale Package (CSP) components.

CAUTION - Operator Safety

A thorough review of the equipment manual and comprehensive training are

mandatory. Daily maintenance is essential. Consult the equipment manual for more

information.

CAUTION - Component Sensitivity

This method may subject the component to extreme temperatures. Evaluate the

component's tolerance to heat prior to using this method.

CAUTION - Circuit Board Sensitivity

PC Boards are made from a great variety of materials. When subjected to the high

temperatures they are susceptible to the following types of damage:

1. Layer delamination.

2. Copper delamination, separation of pads, barrels of inner layers.

3. Burns and solder mask chipping.

4. Warp.

Each circuit board must be treated individually and scrutinized carefully for its

reaction to heat. If a series of circuit boards are to be reworked, the first several

should be handled with extreme care until a reliable procedure is established.

TOOLS & MATERIALS

BGA specific nozzle

Cleaner

Cleaning Wipes

Flux, Liquid

Hot Air rework Station

Hand held Digital Thermometer

Tape, Kapton

Microscope

Oven

Soldering Iron

Solder

Thermocouples

Vacuum Pen

GENERAL NOTES

- Profiles for both removal and replacement of the selected component must be

developed prior to rework. (See section 8.5.2 for instruction)

- Check the board for any heat sensitive components that may be damaged by the

process, especially near the location of rework.

- Profiles are board and site specific. Profiles that are successful on one

board type are not necessarily effective on other assemblies.

PROCEDURE

REMOVAL

- Select the appropriate nozzle and install into the rework station.

- The nozzle should hold the component securely yet allow for expansion during

the process. Custom nozzles may need to be fabricated.

NOTE

Nozzle to part fit is multidimensional. Closely observe the component ball

location relative to the nozzle bottom. Whether the balls protrude or are deeply

recessed into the nozzle may affect part positioning during reflow.

NOTE

Pre bake the board to drive out accumulated

moisture. The length of pre bake will be affected by the board’s environmental

exposure. A pre bake temperature of 75 °C to 100 °C is recommended.

- Place a pre baked board onto the fixture.

- Attach a monitoring and trigger

thermocouples.

- Establish a bottom side, under part

threshold temperature from which to begin the reflow ramp. 140°C underneath the part should correspond

to approximately 90°C at 2" from the nozzle on the board’s top side.

Choosing a starting point in this approximate temperature range will help to

reduce localized warping during BGA ball reflow.

NOTE

Anti static fixture material may be used when coplanarity

problems exist as the circuit board expands above its glass transition temperature (Tg).

- Apply a small amount of liquid flux to all leads of the component.. A

syringe may be used to inject flux under the device.

- Align the device and nozzle.

- Activate the desoldering profile and monitor the board temperature using the

hand held digital thermometer or other appropriate monitoring device.

NOTE

If the bottom temperature exceeds 200°C, terminate the removal process and

check the process parameters.

- Lift the nozzle when reflow temperatures are reached. A vacuum pen may be

used to remove the part if a vacuum tip is not incorporated into the nozzle

itself.

- Clean the area. Remove all flux residue from the site.

SURFACE PREPARATION

NOTE

This procedure

uses eutectic solder alloy bumps to

prepare BGA pads for combination with BGA part balls. For use of solder paste

see section 8.5.4. Component Rework, High Temperature Balled BGA Components.

- Remove all excess solder from the site (See section 7.1.2 Preparation for

Soldering)

- Clean the area.

- Inspect all pads for damage. It is critical that solder mask is not

disturbed between the pad and its via. Solder volume problems may exist if

solder is allowed to escape down the vias.

- Apply liquid flux to the pads.

- Apply new eutectic solder in consistent

bumps to each BGA pad. The bump angle, surface to pad, should be between 30°

and 45°.

REPLACEMENT

- Select the appropriate nozzle and install into the rework station.

- The nozzle should hold the component securely yet allow for expansion during

the process.

NOTE

Pre bake the board to drive out accumulated

moisture. The length of pre bake will be affected by the board’s environmental

exposure. A pre bake temperature of 75 °C to 100 °C is recommended.

NOTE

To remove moisture from components, it is recommended that all parts are baked

per the component manufactures suggestion. Generally, a 24 hour bake at 125°C

will remove most moisture. This will prevent pop-corning or delamination of the

component.

- Place a pre baked board into the fixture.

- Attach monitoring and trigger thermocouples

- Establish a bottom side, under part

threshold temperature from which to begin the reflow ramp. 140°C

underneath the part should correspond

to approximately 90°C at 2" from the nozzle on the board’s top side.

Choosing a starting point in this approximate temperature range will help to

reduce localized warping at BGA ball reflow temperature.

- Align the device and nozzle.

NOTE

If the bottom temperature exceeds 210°C, terminate the replacement and check

the process parameters.

- Lift the nozzle when well below reflow temperatures.

- Ion fans may be used to cool the components and the board.

- Clean the area . Remove all flux residue from the site.

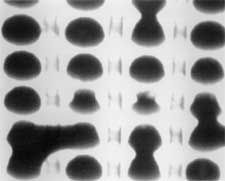

EVALUATION

- Visual examination of the perimeter spheres for joint shape, alignment and

condition.

- Visual examination for part planarity and condition.

- X-ray examination as required for shorting or joint deformities.

See (Figure 2).

- Electrical tests as applicable

- On removed part, visual evaluation of post reflow condition.

|

|

|

Solutions Across the Board

TM

|

|

|

|

Preview our New IPC

Soldering and Rework Skills

Certifications Kits.

Product Class: R/F/W/C

Skill Level: Advanced

Conformance Level: High

Revision: E

Revision Date: July 7, 2000

Repair Service Charge

Plastic Ball Grid Array Component

Figure 1: Commercially available BGA Rework Station

Figure 2: X-ray inspection verifies shorted spheres.

|

|

|